Book binding defines a book’s strength, usability, and appearance. Choosing the right method affects both production quality and reader experience. For publishers, designers, and businesses looking for professional printing, knowing the main binding types is crucial. This guide explains common and specialty binding options, their features, benefits, and ideal applications.

Overview of Different Ways of Book Binding

| Binding Type | Definition | Advantages | Disadvantages | Typical Applications |

| Saddle Stitch | Folded sheets nested and stapled along the spine | Cost-effective, opens flat easily | Limited to ~64 pages, suitable for lighter papers only | Booklets, catalogs, event programs |

| Side Staple | Sheets stapled along the left edge | Opens completely flat, simple to produce | Limited space for spine design | Manuals, workbooks, short reports |

| Perfect / PUR | Pages stacked and glued along spine; PUR uses stronger adhesive | Professional finish, durable | Less flexible, spine may crack if thick | Paperback books, magazines, catalogs |

| Case / Hardcover | Sewn or glued text blocks attached to rigid boards | Highly durable, premium feel | Higher cost, heavier | Textbooks, coffee table books, high-end publications |

| Spiral / Wiro | Continuous coil threaded through punched holes | Opens flat or folds back, flexible | Less formal appearance | Notebooks, planners, interactive manuals |

| Chicago Screw | Metal screws hold pages for modularity | Reusable, sturdy | Bulky, less formal | Portfolios, reference manuals, catalogs |

| Japanese / Stab | Thread sewn along edge | Decorative and unique | Does not open completely flat | Notebooks, photo albums, artistic books |

| Pad / Padded | Sheets glued on one edge to form detachable pad | Easy to tear, functional | Short-term use | Notepads, sketch pads, memo books |

| Singer Sewn / Industrial Sewing | Signatures sewn before cover attachment | Extremely durable, opens flat | Higher cost | Dictionaries, encyclopedias, archival books |

| Section Sewn | Folded sections sewn together then attached to cover | Opens fully, durable | More labor-intensive | Art books, catalogs, academic publications |

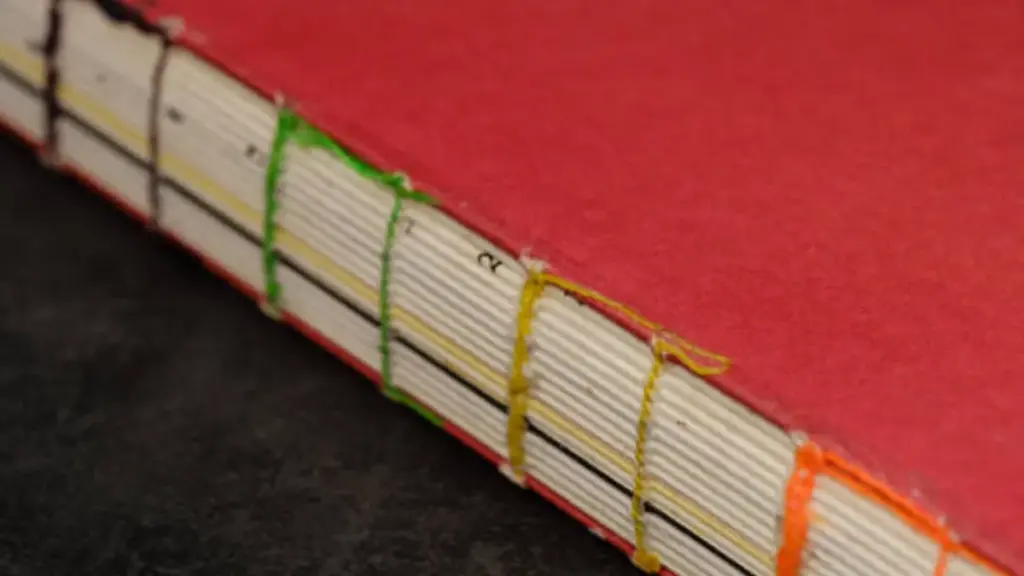

| Coptic Stitch | Sections linked with chain stitches along exposed spine | Opens flat, handcrafted aesthetic | Best for medium-length books | Sketchbooks, journals, artist portfolios |

| Exposed Spine | Stitching left visible on spine | Flat opening, visually striking | Labor-intensive, small batch production | Design books, premium notebooks |

| Quarter / Half | Spine and covers use different materials | Distinctive appearance, durable | Moderate cost | Novels, journals, legal books |

| Burst | Glue applied in strips along spine | Flexible, cost-efficient | Limited to medium thickness | Instructional books, company manuals |

| Custom Boxes / Slipcases / Ring Binders | Protective enclosures or modular covers | Protects books, adds premium feel or modularity | Adds bulk or less formal appearance | Premium editions, portfolios, modular content |

8 Common Types of Book Binding

1. Saddle Stitch Binding

Saddle stitch binding is a simple and cost-efficient method where folded sheets are nested and stapled along the spine. It allows books to open flat easily and supports up to 64 pages with standard 80gsm paper. The exposed spine gives a clean, minimalist look, which can be enhanced with subtle cover designs or graphics.

This method works best with lighter papers, either coated or uncoated. Designers can use the spine for decorative effects or branding. It is ideal for smaller booklets, event programs, or seasonal catalogs where low-cost production and fast turnaround are priorities.

2. Side Staple Binding

Side staple binding secures sheets along the left edge, allowing the book to open completely flat. It can accommodate up to 80 pages, making it suitable for manuals, workbooks, or short reports.

Lightweight cardstock or laminated covers improve durability. While the spine offers limited space for graphics, designers can enhance the cover with color, texture, or foil finishes.

3. Perfect Binding / PUR Binding

Perfect binding is a mechanical process where individual pages are stacked and glued along the spine to create a clean, professional finish. Perfect binding also called PUR binding (Polyurethane Reactive binding). You may not familiar with it. It uses a stronger adhesive to make the book more durable and resistant to temperature changes. This binding supports 48 to 400 pages, depending on paper thickness, and is widely used for paperback books, magazines, reports, and catalogs. It works best with matte, glossy, or uncoated paper, and designers can print titles or logos on the spine, which provides a polished, professional look.

4. Case / Hardcover Binding

Hardcover binding attaches sewn or glued text blocks to rigid boards, often covered with cloth, leather, or laminated paper. It is highly durable and suitable for books that require longevity, like textbooks, coffee table books, and high-end publications.

Designers can add embossing, foil stamping, or dust jackets for extra appeal. Thousands of pages can be handled with proper sewing, and books open flat with minimal strain on the spine. This method combines durability, professional presentation, and premium quality.

5. Spiral / Wiro / Plastic Coil Binding

Spiral or wiro binding threads a continuous coil through punched holes along the spine, allowing books to lay flat or fold back completely. It supports 20–200 pages and works with standard or heavier paper.

Plastic coils are light and flexible, metal coils provide added strength. Designers can customize coil colors or cover translucency for visual appeal. It’s ideal for planners, notebooks, or interactive manuals that require frequent handling.

6. Chicago Screw / Interscrew Binding

Chicago screw binding uses metal screws to hold pages together, allowing easy disassembly and updates. It accommodates 20–200 pages and is ideal for photograph portfolios, reference manuals, restaurant menu, or catalogs.

Thick cardstock or laminated covers improve durability, and screws can be brass, nickel, or coated in black. Designers can combine materials and colors for branding purposes. This binding balances sturdiness with adaptability, making it practical for business and professional presentations.

7. Japanese / Stab Binding

Japanese, or stab, binding involves sewing thread through holes along the edge of the book. It is typically used for notebooks, photo albums, and artistic publications. This method allows decorative stitching and supports books up to around 80 pages.

Although the book is sewn along the edge and does not open completely flat, designers can use various thread colors and stitching patterns to enhance its visual appeal. Stab binding emphasizes craftsmanship and aesthetics, appealing to niche markets where design and uniqueness are important.

8. Pad / Padded Binding

Pad binding stacks sheets and glues them along one edge to form a detachable pad. It is often used for notepads, sketch pads, and memo books. The binding allows clean tearing of individual sheets while keeping the pad stable.

A chipboard or thick backing provides support, and covers can be simple cardstock or padded for comfort. Pad binding is practical for short-term projects or promotional stationery that prioritizes functionality over longevity.

Specialty Types of Book Binding

1. Singer Sewn / Industrial Sewing

Singer sewn, or industrial sewing, stitches signatures together before attaching the cover. This method produces extremely durable books, suitable for dictionaries, encyclopedias, or archival-quality volumes.

Books of thousands of pages can open flat without damaging the spine. High-quality cotton or polyester threads are commonly used, and multiple colors can be applied for decorative purposes. Though more costly, this method ensures long-term durability and professional quality.

2. Section Sewn Binding

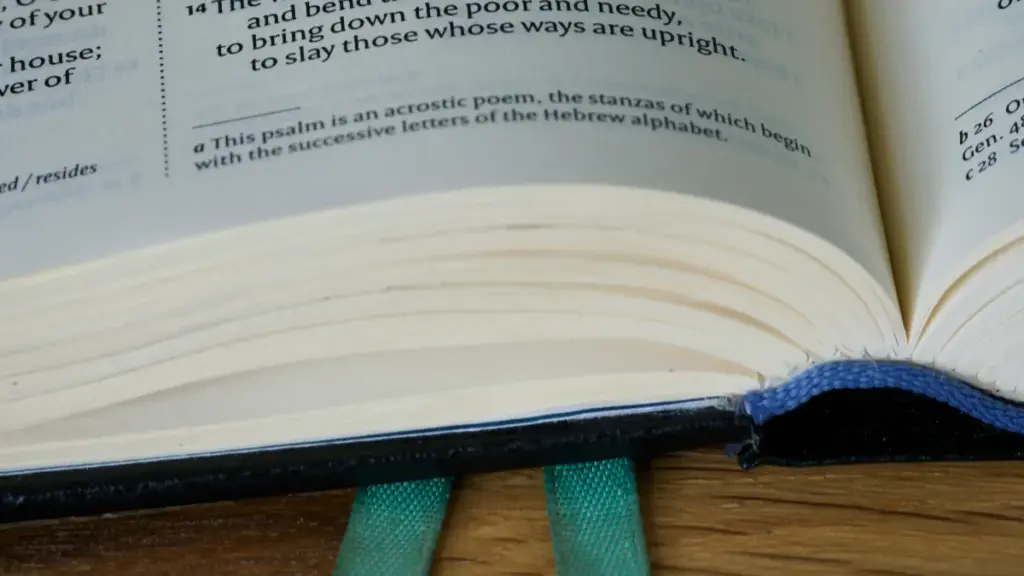

Section sewn binding involves sewing folded sections together, then attaching them to a cover. This technique allows books to open fully regardless of its page count.

It is commonly applied to art books, catalogs, and academic publications. Designers can use endpapers, embossing, or foil stamping to enhance the book’s appearance. Section sewn binding offers a balance of durability and premium presentation.

3. Coptic Stitch Binding

Coptic stitch binding links book sections with chain stitches along an exposed spine. Its main feature is the ability to open flat, making it ideal for sketchbooks, journals, and artist portfolios.

Medium-length books benefit most from this method. Designers can use different thread colors and patterns to add visual interest. Coptic stitch binding combines functional strength with a handcrafted aesthetic.

4. Exposed Spine Binding

Exposed spine binding leaves the stitching visible on the spine, emphasizing craftsmanship. It is often used for design books and premium notebooks, with a minimum of around 32 pages; the binding works best for small to medium-length books due to its complex, labor-intensive process.

Books open completely flat, and designers can highlight thread colors or use contrasting cover materials to enhance visual appeal. This binding showcases transparency in design and offers a unique tactile experience.

5. Quarter Binding / Half Binding

Quarter and half binding use two different materials, typically cloth or leather for the spine and a separate material for the covers. This traditional method suits novels, journals, and legal books.

It supports moderate to thick page counts. Endpapers, embossing, or foil stamping can enhance the luxury feel. This binding combines durability with a distinctive appearance without the full cost of hardcover production.

6. Burst Binding

Burst binding applies glue in strips along the spine to reinforce adhesion while allowing flexibility. It is suitable for booklets of medium thickness or materials that experience frequent page-turning.

It accommodates 100–300 pages depending on paper weight and works with both coated and uncoated sheets. Designers appreciate its cost efficiency and durability, making it practical for instructional books or company manuals.

7. Custom Boxes, Slipcases & Ring Binders

Custom boxes and slipcases are protective enclosures that hold books, keeping them safe from dust, scratches, and wear. They are usually made from sturdy cardboard, chipboard, or laminated paper, sometimes with cloth or leather finishes for a premium look. Ring binders are modular covers that hold punched pages, allowing easy addition or removal of content.

Slipcases provide an elegant presentation and durability but add extra bulk and cost. Ring binders offer flexibility and reusability but are less formal in appearance. Designers can enhance these solutions with printing, embossing, or foil stamping to match branding or aesthetic goals.

How to Choose the Right Book Binding for Your Project

Choosing the right book binding depends on several key factors that affect both the book’s functionality and appearance. Here are the main considerations:

1. Page Count and Thickness – Thinner books with fewer pages are suited for saddle stitch or side staple binding. Thicker books benefit from perfect binding, section sewn, or hardcover binding, which provide strength and durability.

2. Intended Use – Consider how the book will be handled. Notebooks, planners, or manuals that require frequent page-turning often work best with spiral or Chicago screw binding. Books meant for long-term use, like textbooks or premium publications, should use hardcover or sewn bindings.

3. Paper Type – Lighter papers work well with saddle stitch or spiral binding, while thicker or coated papers require stronger adhesive or sewn methods to prevent spine cracking.

4. Aesthetic Goals – Hardcover, Coptic stitch, or exposed spine bindings allow for decorative features like embossing, foil stamping, or colored threads. Designers should match the binding style with the intended visual impact.

5. Budget and Production Volume – Simple methods like saddle stitch or perfect binding are cost-effective for high-volume printing. Specialty bindings such as exposed spine or custom slipcases are more labor-intensive and suited for small batches or premium editions.

Get Expert Advice Here

Working with an experienced printer ensures your book meets both quality and design expectations. Xinyi Printing, founded in 1998, has over 25 years of experience in book and packaging production. Our factory spans 20,000㎡ with 280 skilled employees, capable of producing 5 million books and 6 million packaging boxes monthly. We support sustainable printing practices, including FSC-certified materials and eco-friendly processes. We offer diversified customization options such as paper types, binding type, and printing types, ensuring your project is both functional and visually striking. Trust Xinyi Printing to bring your book vision to life with professionalism and care.