Fabrication avancée de livres imprimés personnalisés & Cahiers

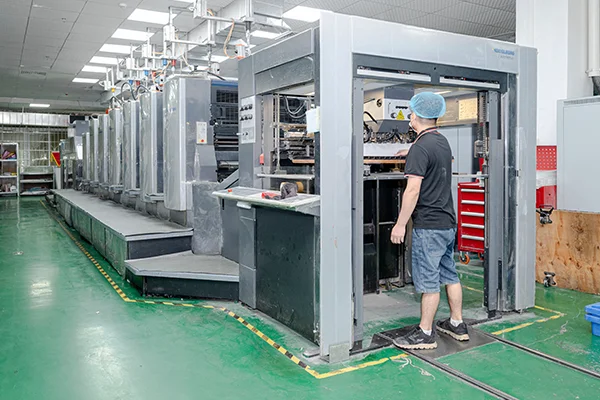

Dédié aux solutions d'impression avancées

Département prépresse: Équipé du système de fabrication de plaques Kodak Super CTP associé à l'étalonnage des couleurs Heidelberg pour une précision des couleurs inégalée.

Presses de pointe: Comprend un Heidelberg de nouvelle génération 6+1 presse à séchage automatique à passage d'huile à bande, deux presses 4 couleurs Komori Lithrone à grande vitesse, et un polyvalent 4+4 presse hybride huit couleurs pour les travaux multitons complexes.

Finition automatisée: Intégration transparente avec des systèmes de reliure ou de couverture rigide entièrement automatiques et six lignes manuelles dédiées pour des détails sur mesure.

Équipement de fabrication avancé

Machine de fabrication de plaques

Appareil de pose de plaques KODAK MAGNUS Q800

- Avantages de la vitesse

- Automatisation avancée

- Avantages de qualité

Processeur de plaque thermique numérique

Fuji LP-1310HII

- Efficacité environnementale

- Automatisation améliorée

- Impression de haute qualité

Machine d'épreuvage de découpe de boîtes de boutique

AokéDCZ721310

- Récemment mis à niveau & Expérience de travail plus rapide

- Equipé d'un écran tactile & Interface machine conviviale

- Conception de machines intégrée & Plus stable et artistique

Traceur jet d'encre grand format

Imprimante HP Designjet T770

- Résolution de sortie de haute qualité

- Performances efficaces

- Convient à diverses applications grand format

- Économie d'énergie pendant le fonctionnement et les modes veille

Cintreuse et poinçonneuse de plaques

TY-200PB

- Efficacité améliorée

- Maximisez les économies de coûts

- ROI amélioré avec 145 Jours

- Fonctionnement convivial

Machine d'épreuvage numérique

EPSON PRO9908

- Système d'encre UltraChrome PRO12

- Tête d'impression Micro TFP à noyau de précision

- Sortie grand format

- Précision des couleurs exceptionnelle

- Compatibilité élevée des médias

- Maintenance automatisée & Opération facile

Machine d'impression en quatre couleurs

Feuillet S40SP

- Perfectionnement en un seul passage (PS) Technologie

- Sortie haute vitesse vers 15,000 feuilles par heure - Impression supérieure

- Maintient une excellente stabilité des couleurs & Reproduction d'images nettes

- Temps de préparation réduit & Minimiser les temps d'arrêt

- Fonctionnement respectueux de l'environnement

- Gamme de substrats polyvalente

Machine d'impression six couleurs et UV

Heidelberg CD102-6+L

- 6-Configuration des couleurs + Unité de coucheuse

- -Large gamme de substrats

- Performances à grande vitesse jusqu'à 15,000 feuilles par heure

- Précision Précision & Cohérence des couleurs

- Fonctionnement respectueux de l'environnement

- Automation & Changements rapides

Lithrone 840 Machine d'impression huit couleurs

Heidelberg LS840P

- 8-Presse perfectionnant les couleurs (4+4 Configuration)

- Automatisation avancée & Interface de fonctionnement intuitive

- Performances à grande vitesse jusqu'à 18,000 feuilles par heure

- Compatibilité polyvalente des substrats

- Couleur précise & Contrôle de qualité

Agrafage à cheval automatique

Encarteuse à cheval Muller Martini

- Vitesse de production élevée jusqu'à 14 000 à 20 000 cycles par heure

- Configuration modulaire et flexible

- Haute qualité de couture

- Automatisation avancée

- Fonctionnement intuitif

- Large gamme de formats

- Alimentation et classement fiables

- Capacités de finition en ligne

- Durabilité et ingénierie suisse

Machine à coudre

Müller Martini Ventura 3215

- Couture de fil à grande vitesse

- Alignement de précision & Piqûre

- Automation & Opération facile

- Flexibilité grand format

- Compatibilité avec les lignes de production automatisées

Machine à plastifier

YONGSHUNYS-108

- Estampage chaud & Découpe en un seul passage

- Haute précision & Précision de l'enregistrement

- Alimentation automatique & Système de livraison

- Forte pression & Construction durable

- Large compatibilité matérielle

Machine de collage automatique

ZY440-A rond

- Pliage automatique & Formation

- Vitesse de productivité élevée Jusqu'à 25 à 35 boîtes par minute

- Système de positionnement de précision

- Compatibilité polyvalente des types de boîtes

- Conception compacte

Poinçonneuse automatique

HB-420

- Formage automatique de boîtes rigides

- Vitesse de production élevée jusqu'à 20 à 30 boîtes par minute

- Positionnement de précision & Formation

- Prend en charge plusieurs types de boîtes

- Contrôle par écran tactile & Système API

- Durable & Conception économe en espace

Machine à relier parfaite

Müller Martini 3006

- Performances de liaison à grande vitesse jusqu'à 6,000 livres par heure

- Excellente qualité de reliure

- Gestion flexible du format de livre

- Système avancé d’application de colle

- Contrôle par écran tactile & Automation

- Compatible avec l'intégration en ligne

Machine de doublure automatique double face

Machine de doublure double face entièrement automatique YASI + Ligne de liaison de stratification YASI SL60

- Collage de précision double face

- Grande vitesse, Fonctionnement continu

- Système d'alimentation en papier intelligent

- Alignement précis & Pliant

- Stratification intégrée & Séchage

- Conception compacte et modulaire

- Système de chauffage économe en énergie

Plieuse

Machine à plier Heidelberg

- Pliage de haute précision

- Configurations pliantes polyvalentes

- Conception modulaire

- Excellente durabilité & Fiabilité

- Fonctionnalités automatisées

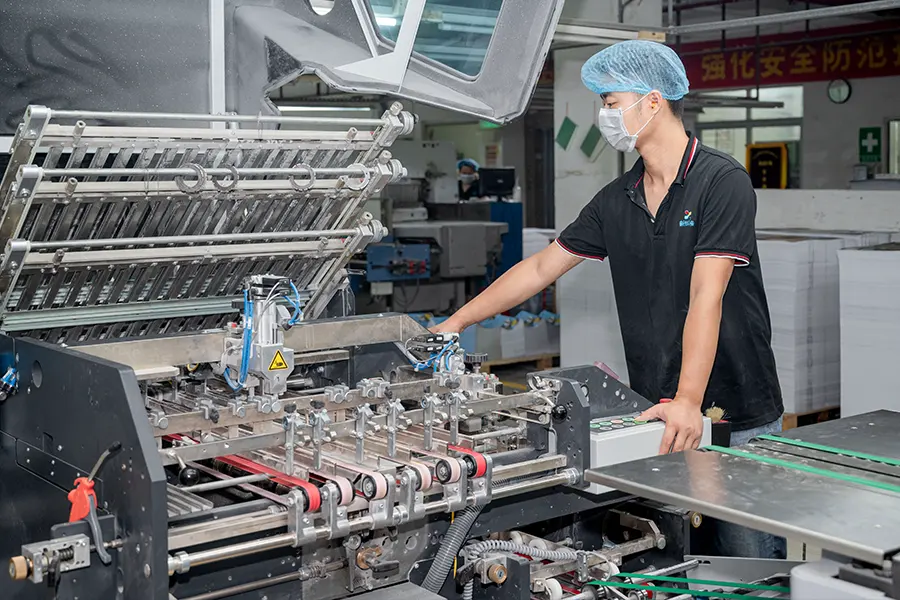

Processus de fabrication d'impression de livres axé sur la qualité

De la préparation des matériaux à la finition, Assurer une qualité de haute qualité, durable, et des produits de livre visuellement attrayants.

01

Impression

Finition de surface

03

Coupure

04

Pliant

05

Obligatoire

06

Contrôle de qualité

07

Emballage & Stockage

08

Expédition

Processus de contrôle de qualité: Assurer l’excellence dans les moindres détails

Des matières premières aux produits finis, nous mettons en œuvre un processus de contrôle de qualité rigoureux pour garantir que chaque étape répond aux normes les plus élevées.

Grâce à des inspections précises et des contrôles stricts, nous livrons en toute sécurité, durable, et des services d'impression durables à nos clients.

Scène 1: Inspection des matières premières & Stockage

Inspection des matières premières & Stockage

- Contrôle de l'humidité: Nous utilisons des instruments d'humidité pour vérifier les niveaux d'humidité optimaux pour le papier., encres, et revêtements, éviter les déformations ou les incohérences d'impression.

- QI (Contrôle qualité entrant): Inspecter le papier des matières premières, encre, films de pelliculage pour détecter les défauts et le respect des spécifications avant stockage en entrepôt.

- Stockage du matériel: Les matériaux approuvés sont enregistrés et stockés dans l'entrepôt de matières premières dans des conditions environnementales contrôlées..

Scène 2: Préparation pré-presse

Préparation pré-presse

- Découpe de papier: Coupez le papier brut aux dimensions requises à l'aide de machines de découpe de précision.

- Imposition (Disposition des plaques): Organisez les pages numériquement pour un alignement optimal des plaques et une impression efficace.

- Exposition de la plaque & Lavage: Créez des plaques d'impression via le transfert de lumière UV des mises en page numériques et le lavage des plaques pour éliminer les produits chimiques résiduels.

Scène 3: Contrôle du processus d'impression

Contrôle du processus d'impression

- Colorimètre: Mesurer l'écart de couleur par rapport aux normes de référence.

- Système de test de couleur: Garantissez la cohérence des couleurs d’un lot à l’autre avec des épreuves principales.

- Compteur de codes à barres: Valider la clarté du code-barres, taille, et numérisabilité.

- Étrier UPM: Surveillez l’uniformité de l’épaisseur du papier pour optimiser la pression et la qualité d’impression.

- IPQC (Contrôle qualité en cours de processus): Effectuer des inspections en temps réel des défauts, tels qu'un mauvais repérage et des taches d'encre.

Scène 4: Traitement post-presse & CQ en cours

Traitement post-presse & CQ en cours

- Traitement de surface: Appliquer des revêtements, comme la stratification brillante/mate, pour la durabilité et l’esthétique.

- Laminage: Lier les feuilles imprimées aux substrats pour une rigidité structurelle.

- Découpe: Façonner les produits à l'aide de matrices de précision pour les dimensions finales.

- Revérification IPQC: Vérifier la précision dimensionnelle, qualité d'adhésion, et l'intégrité de la finition de surface.

Scène 5: Inspection finale & Conditionnement

Inspection finale & Conditionnement

- OCC (Contrôle qualité sortant): Vérifier les livres finis pour vérifier l'intégrité de l'emballage, précision de l'étiquetage, et le respect des spécifications clients.

- Entreposage: Les produits approuvés sont stockés dans l'entrepôt de produits finis dans des conditions climatiques contrôlées..

Certification faisant autorité

L'impression Xinyi est écosécléficielle, attaché à des pratiques durables, et utilise des matériaux verts et des processus économes en énergie pour la qualité, Impression de livre conscient de l'éco-.

Explorez la différence Xinyi

Excellence technique

Propulsé par Heidelberg, Presses numériques Komori et autres équipements de production professionnels, Nous nous assurons de qualité conçue de précision et Fabrication à haute efficacité

Flexibilité de coût intelligent

Nous permettons aux partenariats OEM évolutifs via des workflows de production maigres et des réseaux logistiques intégrés pour répondre aux demandes dynamiques du marché.

Service centré sur le client

Nous fournissons un support global transparent à travers 24/7 équipes multilingues, jumelé avec Personnalisation de bout en boutDe la sélection des matériaux à l'ingénierie de précision.

Innovation durable

Nous pionnière des articles certifiés FSC, Soja & Inks et adhésifs UV qui se rencontrent stricts critères de durabilité, rigoureusement aligné avec l'UE & US Eco-Standards.