Fabricação Avançada de Livros Impressos Personalizados & Notebooks

Dedicado a soluções avançadas de impressão

Departamento de Pré-impressão: Equipado com sistema de gravação de chapas Kodak Super CTP emparelhado com calibração de cores Heidelberg para precisão de cores incomparável.

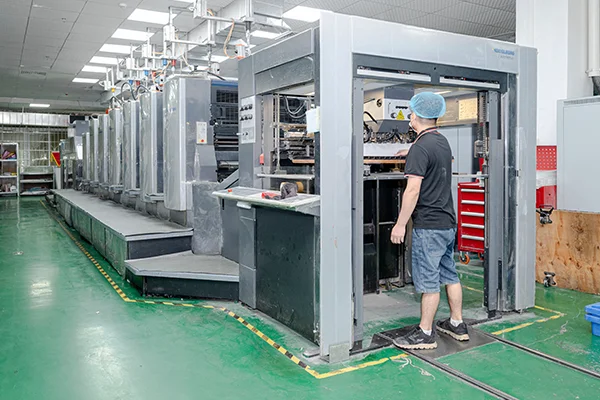

Prensas de última geração: Inclui uma Heidelberg de última geração 6+1 prensa de secagem automática com passagem de óleo para correia, duas impressoras Komori Lithrone de 4 cores de alta velocidade, e um versátil 4+4 impressora híbrida de oito cores para trabalhos multitons complexos.

Acabamento Automatizado: Integração perfeita com sistemas de encadernação ou capa dura totalmente automáticos e seis linhas manuais dedicadas para detalhes personalizados.

Equipamento de fabricação avançado

Máquina para fabricar placas

Colocador de placas KODAK MAGNUS Q800

- Vantagens de velocidade

- Automação Avançada

- Vantagens de qualidade

Processador de Placa Térmica Digital

Fuji LP-1310HII

- Eficiência Ambiental

- Automação aprimorada

- Impressão de saída de alta qualidade

Máquina de impermeabilização de corte de caixa boutique

AokeDCZ721310

- Recentemente atualizado & Experiência de trabalho mais rápida

- Equipado com tela sensível ao toque & Interface de máquina amigável

- Projeto Integrado de Máquina & Mais estável e artístico

Plotadora jato de tinta de grande formato

Impressora HP Designjet T770

- Resolução de saída de alta qualidade

- Desempenho Eficiente

- Adequado para diversas aplicações de grande formato

- Economia de energia durante a operação e nos modos de espera

Máquina para dobrar e perfurar placas

TY-200PB

- Eficiência aprimorada

- Maximize a economia de custos

- ROI melhorado com 145 Dias

- Operação amigável

Máquina de prova digital

EPSON PRO9908

- Sistema de tinta UltraChrome PRO12

- Cabeça de impressão Precision Core Micro TFP

- Saída de grande formato

- Precisão de cores excepcional

- Alta compatibilidade de mídia

- Manutenção Automatizada & Operação fácil

Máquina de impressão em quatro cores

deslizamento S40SP

- Aperfeiçoamento de passagem única (SP) Tecnologia

- Saída de alta velocidade para 15,000 folhas por hora - Impressão Superior

- Mantém excelente estabilidade de cores & Reprodução de imagem nítida

- Tempo de preparação reduzido & Minimize o tempo de inatividade

- Operação ecologicamente correta

- Gama versátil de substratos

Máquina de impressão UV e de seis cores

Heidelberg CD102-6+L

- 6-Configuração de cores + Unidade de revestimento

- -Ampla gama de substratos

- Desempenho de alta velocidade até 15,000 folhas por hora

- Precisão Precisão & Consistência de cores

- Operação ecologicamente correta

- Automação & Trocas rápidas

Litrono 840 Máquina de impressão de oito cores

Heidelberg LS840P

- 8-Imprensa de aperfeiçoamento de cores (4+4 Configuração)

- Automação Avançada & Interface de operação intuitiva

- Desempenho de alta velocidade até 18,000 folhas por hora

- Compatibilidade versátil de substrato

- Cor precisa & Controle de qualidade

Costura-sela automática

Muller Martini Sela-costurador

- Alta velocidade de produção de até 14.000 a 20.000 ciclos por hora

- Configuração modular e flexível

- Alta qualidade de costura

- Automação Avançada

- Operação intuitiva

- Ampla gama de formatos

- Alimentação e agrupamento confiáveis

- Capacidades de acabamento em linha

- Durabilidade e Engenharia Suíça

Máquina de costura

Müller Martini Ventura 3215

- Costura com linha em alta velocidade

- Alinhamento de precisão & Costura

- Automação & Operação fácil

- Grande flexibilidade de formato

- Compatibilidade com linhas de produção automatizadas

Máquina de laminação

YONGSHUN YS-108

- Carimbo quente & Corte e vinco em uma passagem

- Alta Precisão & Precisão de registro

- Alimentação Automática & Sistema de entrega

- Pressão Forte & Construção Durável

- Ampla compatibilidade de materiais

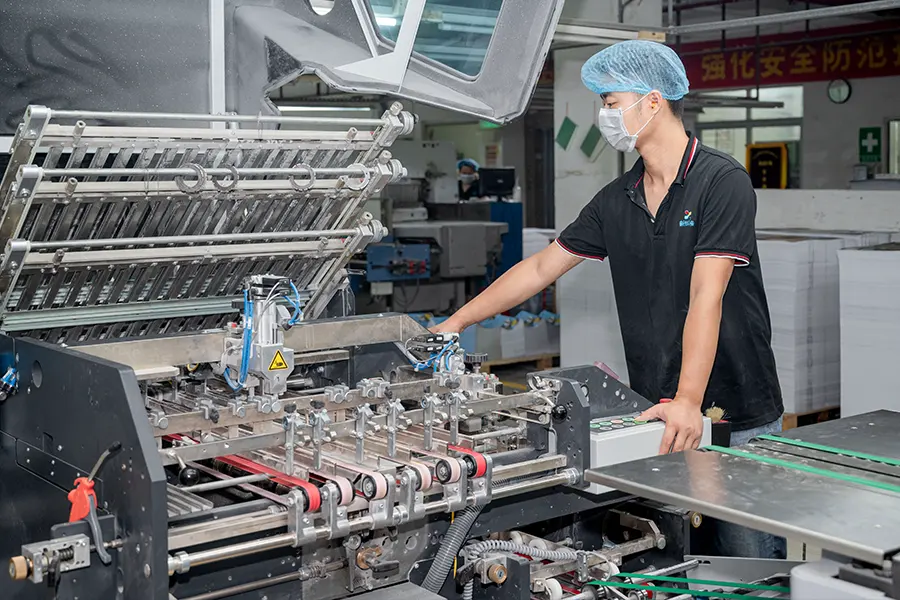

Máquina de colagem automática

Rodada ZY440-A

- Dobragem Automática & Formando

- Velocidade de alta produtividade Até 25–35 caixas por minuto

- Sistema de posicionamento de precisão

- Compatibilidade versátil de tipo de caixa

- Design Compacto

Máquina de perfuração automática

HB-420

- Formação automática de caixa rígida

- Alta velocidade de produção Até 20–30 caixas por minuto

- Posicionamento de precisão & Formando

- Suporta vários tipos de caixa

- Controle de tela sensível ao toque & Sistema CLP

- Durável & Design com eficiência de espaço

Máquina de encadernação perfeita

Müller Martini 3006

- Desempenho de encadernação de alta velocidade até 6,000 livros por hora

- Excelente qualidade de encadernação

- Manuseio flexível de formatos de livros

- Sistema avançado de aplicação de cola

- Controle de tela sensível ao toque & Automação

- Capacidade de integração inline

Máquina automática de forro frente e verso

Máquina de revestimento dupla face totalmente automática YASI + Linha de ligação de laminação YASI SL60

- Colagem de Precisão Dupla Face

- De alta velocidade, Operação Contínua

- Sistema Inteligente de Alimentação de Papel

- Alinhamento Preciso & Dobrar

- Laminação Integrada & Secagem

- Design compacto e modular

- Sistema de aquecimento com eficiência energética

Máquina Dobrável

Máquina Dobradora Heidelberg

- Dobragem de alta precisão

- Configurações versáteis de dobramento

- Projeto Modular

- Excelente durabilidade & Confiabilidade

- Recursos automatizados

Processo de fabricação de impressão de livros orientados para a qualidade

Da preparação do material ao acabamento, garantindo alta qualidade, durável, e produtos de livros visualmente atraentes.

01

Impressão

Acabamento superficial

03

Corte de morto

04

Dobrar

05

Vinculativo

06

Controle de qualidade

07

Embalagem & Armazenar

08

Envio

Processo de Controle de Qualidade: Garantindo Excelência em Cada Detalhe

Das matérias-primas aos produtos acabados, implementamos um rigoroso processo de controle de qualidade para garantir que cada etapa atenda aos mais altos padrões.

Através de inspeções precisas e verificações rigorosas, entregamos com segurança, durável, e serviços de impressão sustentáveis aos nossos clientes.

Estágio 1: Inspeção de Matérias Primas & Armazenar

Inspeção de Matérias Primas & Armazenar

- Controle de umidade: Usamos instrumentos de umidade para verificar os níveis ideais de umidade para papel, tintas, e revestimentos, evitando deformações ou inconsistências de impressão.

- QI (Controle de qualidade de entrada): Inspecione o papel das matérias-primas, tinta, filmes de laminação quanto a defeitos e conformidade com as especificações antes do armazenamento em armazém.

- Armazenamento de Materiais: Os materiais aprovados são registrados e armazenados no Armazém de Matérias-Primas sob condições ambientais controladas.

Estágio 2: Preparação Pré-Impressão

Preparação Pré-Impressão

- Corte de papel: Corte o papel bruto nas dimensões exigidas usando máquinas de corte de precisão.

- Imposição (Layout da placa): Organize as páginas digitalmente para um alinhamento ideal da chapa e uma impressão eficiente.

- Exposição da Placa & Lavando: Crie chapas de impressão por meio de transferência de luz UV de layouts digitais e lavagem de chapas para remover produtos químicos residuais.

Estágio 3: Controle de processo de impressão

Controle de processo de impressão

- Colorímetro: Meça o desvio de cor em relação aos padrões de referência.

- Sistema de teste de cores: Garanta a consistência de cores entre lotes com provas mestre.

- Medidor de código de barras: Validar a clareza do código de barras, tamanho, e escaneabilidade.

- Paquímetro UPM: Monitore a uniformidade da espessura do papel para otimizar a pressão e a qualidade da impressão.

- IPQC (Controle de qualidade em processo): Realize inspeções em tempo real em busca de defeitos, como registro incorreto e manchas de tinta.

Estágio 4: Processamento pós-impressão & Controle de qualidade em processo

Processamento pós-impressão & Controle de qualidade em processo

- Tratamento de superfície: Aplicar revestimentos, como laminação brilhante/fosca, para durabilidade e estética.

- Laminação: Una folhas impressas a substratos para obter rigidez estrutural.

- Corte e vinco: Moldar produtos usando matrizes de precisão para dimensões finais.

- Nova verificação do IPQC: Verifique a precisão dimensional, qualidade de adesão, e integridade do acabamento superficial.

Estágio 5: Inspeção Final & Embalagem

Inspeção Final & Embalagem

- OCC (Controle de qualidade de saída): Audite livros finalizados quanto à integridade da embalagem, precisão de rotulagem, e conformidade com as especificações do cliente.

- Armazenagem: Os produtos aprovados são armazenados no Armazém de Produtos Acabados sob condições climatizadas..

Certificação Autorizada

A impressão Xinyi tem certificação ecológica, comprometido com práticas sustentáveis, e utiliza materiais verdes e processos energeticamente eficientes para qualidade, impressão de livros ecologicamente conscientes.

Explore a diferença Xinyi

Excelência técnica

Alimentado por Heidelberg, Imprensa digital Komori e outros equipamentos de produção profissional, Garantimos a qualidade de engenharia de precisão e Fabricação de alta eficiência

Flexibilidade de custo-inteligência

Ativamos parcerias OEM escaláveis por meio de fluxos de trabalho de produção enxuta e redes de logística integradas para atender às demandas dinâmicas do mercado.

Serviço centrado no cliente

Entregamos suporte global sem costura por meio 24/7 equipes multilíngues, emparelhado com Personalização de ponta a pontaDa seleção de material à engenharia de precisão.

Inovação sustentável

Nós pioneiros em papéis certificados pelo FSC, Soja & Tintas UV e adesivos que encontram rigorosos Critérios de sustentabilidade, rigorosamente alinhado com a UE & EUA eco-padrões.