Advanced Manufacturing for Custom Printed Books & Notebooks

Dedicated to Advanced Printing Solutions

Prepress Department: Equipped with Kodak Super CTP platemaking system paired with Heidelberg color calibration for unmatched color accuracy.

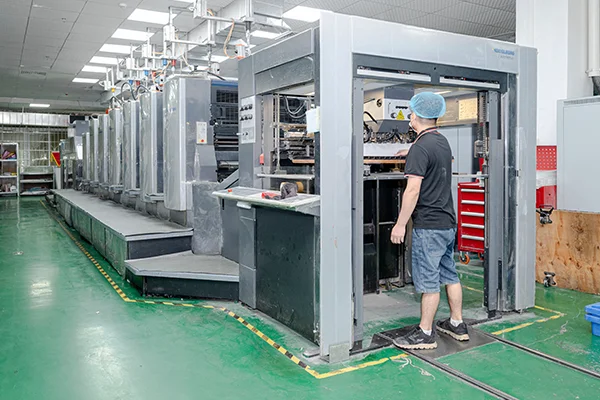

Cutting-Edge Presses: Includes a next-gen Heidelberg 6+1 belt oil-passing auto-drying press, two high-speed Komori Lithrone 4-color presses, and a versatile 4+4 eight-color hybrid press for complex multitone jobs.

Automated Finishing: Seamless integration with fully automatic binding or hardcover systems and six dedicated manual lines for bespoke detailing.

Advanced Manufacturing Equipment

Plate Making Machine

KODAK MAGNUS Q800 Platesetter

- Speed Advantages

- Advanced Automation

- Quality Advantages

Digital Thermal Plate Processor

Fuji LP-1310HII

- Environmental Efficiency

- Enhanced Automation

- High-Quality Outputprinting

Boutique Box Cutting Proofing Machine

AokeDCZ721310

- Newly Upgraded & Faster Working Experience

- Equipped with Touch Screen & Friendly Machine Interface

- Integrated Machine Design & More Stable and Artistic

Large-format Inkjet Plotter

HP Designjet T770 Printer

- High-Quality Output Resolution

- Efficient Performance

- Suitable For Various Large-format Applications

- Energy-saving During Operation and Standby Modes

Plate Bending and Punching Machine

TY-200PB

- Enhanced Efficiency

- Maximize Cost Savings

- Improved ROI With 145 Days

- User-Friendly Operation

Digital Proofing Machine

EPSON PRO9908

- UltraChrome PRO12 Ink System

- Precision Core Micro TFP Printhead

- Large Format Output

- Exceptional Color Accuracy

- High Media Compatibility

- Automated Maintenance & Easy Operation

Four Color Printing Machine

LITHRONE S40SP

- Single-Pass Perfecting (SP) Technology

- High-Speed Output to 15,000 sheets per hour-Superior Print

- Maintains Excellent Color Stability & Sharp Image Reproduction

- Reduced Make-Ready Time & Minimize Downtime

- Environmentally Friendly Operation

- Versatile Substrate Range

Six Color and UV Printing Machine

Heidelberg CD102-6+L

- 6-Color Configuration + Coater Unit

- -Wide Substrate Range

- High-Speed Performance Up to 15,000 sheets per hour

- Accuracy Precision & Color Consistency

- Environmentally Friendly Operation

- Automation & Quick Changeovers

Lithrone 840 Eight Color Printing Machine

Heidelberg LS840P

- 8-Color Perfecting Press (4+4 Configuration)

- Advanced Automation & Intuitive Operation Interface

- High-Speed Performance Up to 18,000 sheets per hour

- Versatile Substrate Compatibility

- Accurate Color & Quality Control

Automatic Saddle Stitch

Muller Martini Saddle Stitcher

- High Production Speed up to 14,000–20,000 cycles per hour

- Modular and Flexible Configuration

- High Stitching Quality

- Advanced Automation

- Intuitive Operation

- Wide Range of Formats

- Reliable Feeding and Collation

- Inline Finishing Capabilities

- Durability and Swiss Engineering

Sewing Machine

Muller Martini Ventura 3215

- High-Speed Thread Sewing

- Precision Alignment & Stitching

- Automation & Easy Operation

- Wide Format Flexibility

- Compatibility With Automated Production Lines

Lamination Machine

YONGSHUN YS-108

- Hot Stamping & Die-Cutting in One Pass

- High Precision & Registration Accuracy

- Automatic Feeding & Delivery System

- Strong Pressure & Durable Construction

- Wide Material Compatibility

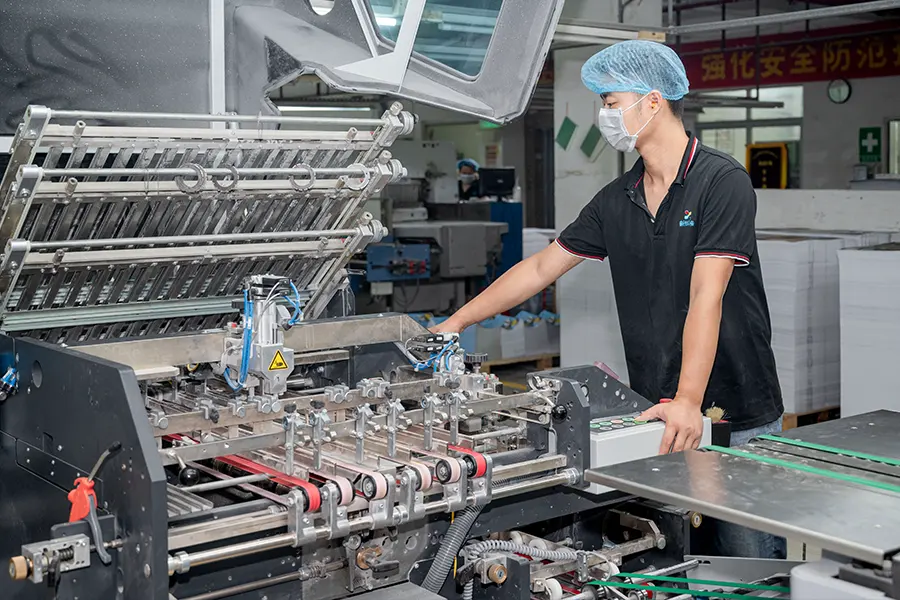

Automatic Pasting Machine

Runda ZY440-A

- Automatic Folding & Forming

- High Productivity Speed Up to 25–35 boxes per minute

- Precision Positioning System

- Versatile Box Type Compatibility

- Compact Design

Auto-punching Machine

HB-420

- Automatic Rigid Box Forming

- High Production Speed Up to 20–30 boxes per minute

- Precision Positioning & Forming

- Supports Multiple Box Types

- Touchscreen Control & PLC System

- Durable & Space-Efficient Design

Perfect Binding Machine

Muller Martini 3006

- High-Speed Binding Performance up to 6,000 books per hour

- Excellent Binding Quality

- Flexible Book Format Handling

- Advanced Glue Application System

- Touchscreen Control & Automation

- Inline Integration Capable

Automatic Double-Sided Lining Machine

YASI Fully Automatic Double-Sided Lining Machine + YASI Laminating Linkage Line SL60

- Dual-Sided Precision Gluing

- High-Speed, Continuous Operation

- Intelligent Paper Feeding System

- Accurate Alignment & Folding

- Integrated Lamination & Drying

- Compact and Modular Design

- Energy Efficient Heating System

Folding Machine

Heidelberg Folding Machine

- High Precision Folding

- Versatile Folding Configurations

- Modular Design

- Excellent Durability & Reliability

- Automated Features

Quality-Driven Books Printing Manufacturing Process

From material preparation to finishing, ensuring high-quality, durable, and visually appealing book products.

01

Printing

Surface Finishing

03

Die Cutting

04

Folding

05

Binding

06

Quality Control

07

Packing & Storage

08

Shipping

Quality Control Process: Ensuring Excellence in Every Detail

From raw materials to finished products, we implement a rigorous quality control process to ensure every step meets the highest standards.

Through precise inspections and strict checks, we deliver safe, durable, and sustainable printing services to our clients.

Stage 1: Raw Materials Inspection & Storage

Raw Materials Inspection & Storage

- Moisture Control: We use Moisture Instruments to verify optimal humidity levels for paper, inks, and coatings, preventing warping or print inconsistencies.

- IQC (Incoming Quality Control): Inspect raw materials paper, ink, lamination films for defects and compliance with specifications before warehouse storage.

- Material Storage: Approved materials are logged and stored in the Raw Material Warehouse under controlled environmental conditions.

Stage 2: Pre-Press Preparation

Pre-Press Preparation

- Paper Cutting: Trim raw paper to required dimensions using precision cutting machines.

- Imposition (Plate Layout): Arrange pages digitally for optimal plate alignment and efficient printing.

- Plate Exposure & Washing: Create printing plates via UV light transfer of digital layouts and plate washing to remove residual chemicals.

Stage 3: Printing Process Control

Printing Process Control

- Colorimeter: Measure color deviation against reference standards.

- Color Test System: Ensure batch-to-batch color consistency with master proofs.

- Bar Code Meter: Validate barcode clarity, size, and scannability.

- UPM Caliper: Monitor paper thickness uniformity to optimize print pressure and quality.

- IPQC (In-Process Quality Control): Conduct real-time inspections for defects, such as misregistration and ink smudging.

Stage 4: Post-Press Processing & In-Process QC

Post-Press Processing & In-Process QC

- Surface Treatment: Apply coatings, such as gloss/matte lamination, for durability and aesthetics.

- Lamination: Bond printed sheets to substrates for structural rigidity.

- Die-Cutting: Shape products using precision dies for final dimensions.

- IPQC Recheck: Verify dimensional accuracy, adhesion quality, and surface finish integrity.

Stage 5: Final Inspection & Packaging

Final Inspection & Packaging

- OQC (Outgoing Quality Control): Audit finished books for packaging integrity, labeling accuracy, and compliance with client specifications.

- Warehousing: Approved products are stored in the Finished Goods Warehouse under climate-controlled conditions.

Authoritative Certification

Xinyi Printing is eco-certified, committed to sustainable practices, and uses green materials and energy-efficient processes for quality, eco-conscious book printing.

Explore the Xinyi Difference

Technical Excellence

Powered by Heidelberg, Komori digital presses and other professional production equipment, we ensure precision-engineered quality and high-efficiency manufacturing

Cost-Smart Flexibility

We enable scalable OEM partnerships through lean production workflows and integrated logistics networks to meet dynamic market demands.

Client-Centric Service

We deliver seamless global support through 24/7 multilingual teams, paired with end-to-end customization from material selection to precision engineering.

Sustainable Innovation

We pioneer FSC-certified papers, Soy & UV inks and adhesives that meet strict sustainability criteria, rigorously aligned with EU & US eco-standards.