Advanced Manufacturing for Custom Printed Books & ノートブック

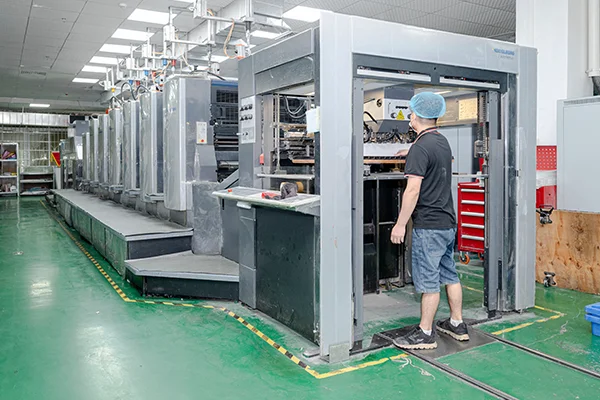

Powered by cutting-edge technology, including Heidelberg presses and Muller Martini binding systems, Xinyi combines decades of expertise in bespoke printing to deliver unparalleled craftsmanship for custom books and notebooks. With vertically integrated production, we ensure strict quality control, cost efficiency, and rapid turnaround.

Dedicated to Advanced Printing Solutions

Our 20,000㎡ factory is equipped with globally renowned production systems, ensuring industrial-grade precision,efficiency and highly customized detailing.

Prepress Department: Equipped with Kodak Super CTP platemaking system paired with Heidelberg color calibration for unmatched color accuracy.

Cutting-Edge Presses: Includes a next-gen Heidelberg 6+1 belt oil-passing auto-drying press, two high-speed Komori Lithrone 4-color presses, and a versatile 4+4 eight-color hybrid press for complex multitone jobs.

Automated Finishing: Seamless integration with fully automatic binding or hardcover systems and six dedicated manual lines for bespoke detailing.

Prepress Department: Equipped with Kodak Super CTP platemaking system paired with Heidelberg color calibration for unmatched color accuracy.

Cutting-Edge Presses: Includes a next-gen Heidelberg 6+1 belt oil-passing auto-drying press, two high-speed Komori Lithrone 4-color presses, and a versatile 4+4 eight-color hybrid press for complex multitone jobs.

Automated Finishing: Seamless integration with fully automatic binding or hardcover systems and six dedicated manual lines for bespoke detailing.

印刷業界で

0

+ 年

統合工場

0

+ ㎡

毎月の容量を本

0

+

プロのスタッフ

0

+

Advanced Manufacturing Equipment

Our factory is equipped with the latest in printing production technology, ensuring efficiency and high-quality output.

Plate Making Machine

KODAK MAGNUS Q800 Platesetter

Capacity: 40 sheets per hour

Key Advantages:

- Speed Advantages

- Advanced Automation

- Quality Advantages

デジタルサーマルプレートプロセッサ

富士lp-1310hii

Capacity: 40 sheets per hour

Key Advantages:

- 環境効率

- Enhanced Automation

- High-Quality Outputprinting

Boutique Box Cutting Proofing Machine

AokeDCZ721310

Capacity: 1350mm/S

Key Advantages:

- Newly Upgraded & Faster Working Experience

- Equipped with Touch Screen & Friendly Machine Interface

- Integrated Machine Design & More Stable and Artistic

Large-format Inkjet Plotter

HP Designjet T770 Printer

Capacity: Resulation 2400*1200

Key Advantages:

- High-Quality Output Resolution

- Efficient Performance

- Suitable For Various Large-format Applications

- Energy-saving During Operation and Standby Modes

Plate Bending and Punching Machine

TY-200PB

Capacity: Suitable For All Print Machine

Key Advantages:

- Enhanced Efficiency

- Maximize Cost Savings

- Improved ROI With 145 Days

- User-Friendly Operation

Digital Proofing Machine

EPSON PRO9908

Capacity: Resolution of 2880*1440

Key Advantages:

- UltraChrome PRO12 Ink System

- Precision Core Micro TFP Printhead

- Large Format Output

- Exceptional Color Accuracy

- High Media Compatibility

- Automated Maintenance & Easy Operation

Four Color Printing Machine

S40SPスリップ

Capacity: 80,000 に 100,000 copies per shift

Key Advantages:

- Single-Pass Perfecting (SP) Technology

- High-Speed Output to 15,000 sheets per hour-Superior Print

- Maintains Excellent Color Stability & Sharp Image Reproduction

- Reduced Make-Ready Time & Minimize Downtime

- 環境に優しい操作

- Versatile Substrate Range

Six Color and UV Printing Machine

Heidelberg CD102-6+L

Capacity: 50,000 に 80,000 copies per shift

Key Advantages:

- 6-Color Configuration + Coater Unit

- -Wide Substrate Range

- High-Speed Performance Up to 15,000 sheets per hour

- Accuracy Precision & Color Consistency

- 環境に優しい操作

- Automation & Quick Changeovers

Lithrone 840 Eight Color Printing Machine

Heidelberg LS840P

Capacity: 50,000 に 80,000 copies per shift

Key Advantages:

- 8-Color Perfecting Press (4+4 Configuration)

- Advanced Automation & Intuitive Operation Interface

- High-Speed Performance Up to 18,000 sheets per hour

- Versatile Substrate Compatibility

- Accurate Color & 品質管理

Automatic Saddle Stitch

Muller Martini Saddle Stitcher

Capacity: 80,000 に 100,000 copies per shift

Key Advantages:

- High Production Speed up to 14,000–20,000 cycles per hour

- Modular and Flexible Configuration

- High Stitching Quality

- Advanced Automation

- Intuitive Operation

- Wide Range of Formats

- Reliable Feeding and Collation

- Inline Finishing Capabilities

- Durability and Swiss Engineering

Sewing Machine

Muller Martini Ventura 3215

Capacity: 5,000 cycles per hour

Key Advantages:

- High-Speed Thread Sewing

- Precision Alignment & Stitching

- Automation & Easy Operation

- Wide Format Flexibility

- Compatibility With Automated Production Lines

Lamination Machine

YONGSHUN YS-108

Capacity: 50,000 copies per shift

Key Advantages:

- ホットスタンピング & Die-Cutting in One Pass

- High Precision & Registration Accuracy

- Automatic Feeding & Delivery System

- Strong Pressure & Durable Construction

- Wide Material Compatibility

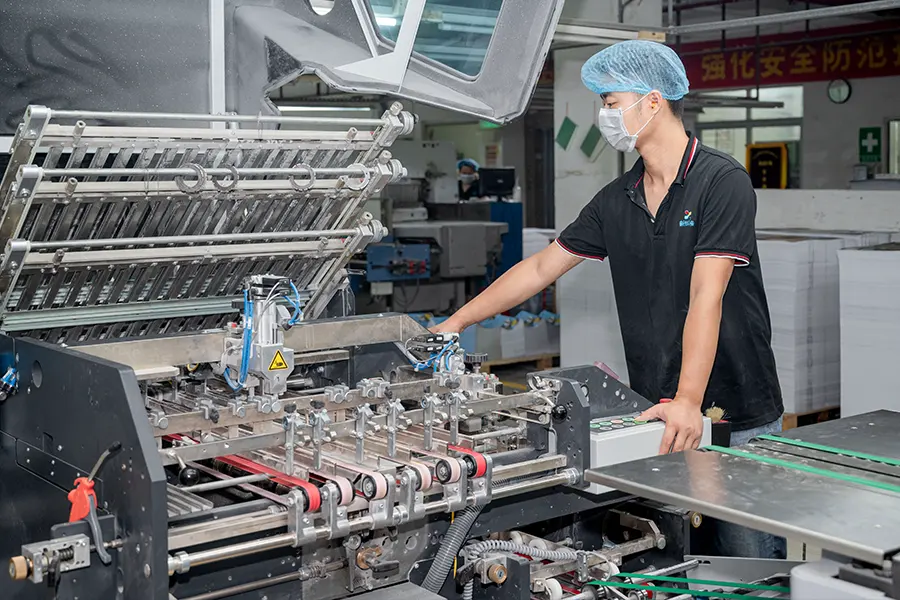

Automatic Pasting Machine

Runda ZY440-A

Capacity: Resulation 2400*1200

Key Advantages:

- Automatic Folding & Forming

- High Productivity Speed Up to 25–35 boxes per minute

- Precision Positioning System

- Versatile Box Type Compatibility

- Compact Design

Auto-punching Machine

HB-420

Capacity: 20,000 copies per shift

Key Advantages:

- Automatic Rigid Box Forming

- High Production Speed Up to 20–30 boxes per minute

- Precision Positioning & Forming

- Supports Multiple Box Types

- Touchscreen Control & PLC System

- 耐久性 & Space-Efficient Design

Perfect Binding Machine

Muller Martini 3006

Capacity: 40,000 copies per shift

Key Advantages:

- High-Speed Binding Performance up to 6,000 books per hour

- Excellent Binding Quality

- Flexible Book Format Handling

- Advanced Glue Application System

- Touchscreen Control & Automation

- Inline Integration Capable

自動両面ライニングマシン

YASI Fully Automatic Double-Sided Lining Machine + YASI Laminating Linkage Line SL60

Capacity: 10,000 copies per shift

Key Advantages:

- Dual-Sided Precision Gluing

- High-Speed, Continuous Operation

- Intelligent Paper Feeding System

- Accurate Alignment & 折りたたみ

- Integrated Lamination & Drying

- Compact and Modular Design

- Energy Efficient Heating System

Folding Machine

Heidelberg Folding Machine

Capacity: 100,000 copies per shift

Key Advantages:

- High Precision Folding

- Versatile Folding Configurations

- Modular Design

- Excellent Durability & Reliability

- Automated Features

品質駆動型の本印刷製造プロセス

材料の準備から仕上げまで, 高品質の確保, 耐久性, 視覚的に魅力的な本製品.

01

印刷

High-volume printing on Heidelberg 6C & Komori 4/8C presses with ISO-certified color precision.

02

表面仕上げ

UV coating, 箔押し & lamination for premium texture, scratch resistance, and elevated brand perception.

03

ダイカット

Precision trimming for custom shapes and sizes, ensuring they meet the specified design requirements.

04

折りたたみ

Folding is performed using fully automatic folding machines, ensuring precise and accurate fold lines for a perfect finish.

05

バインディング

Pages collated into folded sheets, sewn with thread, glued to covers, and trimmed for clean edges.

06

品質管理

Each printed item undergoes a rigorous inspection process to check for color accuracy, print quality and cutting precision.

07

パッキング & ストレージ

Once approved, the printed products are carefully packaged to protect them during transportation and storage.

08

配送

Shipping the packaged products to our customers, ensuring timely and secure delivery to their destination.

Quality Control Process: Ensuring Excellence in Every Detail

From raw materials to finished products, we implement a rigorous quality control process to ensure every step meets the highest standards.

Through precise inspections and strict checks, we deliver safe, 耐久性, and sustainable printing services to our clients.

Stage 1: Raw Materials Inspection & ストレージ

Raw Materials Inspection & ストレージ

- Moisture Control: We use Moisture Instruments to verify optimal humidity levels for paper, inks, およびコーティング, preventing warping or print inconsistencies.

- IQC (Incoming Quality Control): Inspect raw materials paper, ink, lamination films for defects and compliance with specifications before warehouse storage.

- Material Storage: Approved materials are logged and stored in the Raw Material Warehouse under controlled environmental conditions.

Stage 2: Pre-Press Preparation

Pre-Press Preparation

- Paper Cutting: Trim raw paper to required dimensions using precision cutting machines.

- Imposition (Plate Layout): Arrange pages digitally for optimal plate alignment and efficient printing.

- Plate Exposure & Washing: Create printing plates via UV light transfer of digital layouts and plate washing to remove residual chemicals.

Stage 3: Printing Process Control

Printing Process Control

- Colorimeter: Measure color deviation against reference standards.

- Color Test System: Ensure batch-to-batch color consistency with master proofs.

- Bar Code Meter: Validate barcode clarity, size, and scannability.

- UPM Caliper: Monitor paper thickness uniformity to optimize print pressure and quality.

- IPQC (In-Process Quality Control): Conduct real-time inspections for defects, such as misregistration and ink smudging.

Stage 4: Post-Press Processing & In-Process QC

Post-Press Processing & In-Process QC

- Surface Treatment: Apply coatings, such as gloss/matte lamination, for durability and aesthetics.

- ラミネーション: Bond printed sheets to substrates for structural rigidity.

- Die-Cutting: Shape products using precision dies for final dimensions.

- IPQC Recheck: Verify dimensional accuracy, adhesion quality, and surface finish integrity.

Stage 5: Final Inspection & Packaging

Final Inspection & Packaging

- OQC (Outgoing Quality Control): Audit finished books for packaging integrity, labeling accuracy, and compliance with client specifications.

- Warehousing: Approved products are stored in the Finished Goods Warehouse under climate-controlled conditions.

権威ある認証

Xinyi印刷は環境認証です, 持続可能な慣行にコミットしました, 緑色の材料とエネルギー効率の高いプロセスを品質に使用します, 環境に配慮した本の印刷.

Xinyiの違いを調べてください

技術的な卓越性

ハイデルベルクを搭載, コモリデジタルプレスおよびその他の専門的な生産機器, 精密に設計された品質を確保します 高効率製造

コストスマートの柔軟性

無駄のない生産ワークフローと統合されたロジスティクスネットワークを通じてスケーラブルなOEMパートナーシップを有効にして、動的な市場の需要を満たすことができます.

クライアント中心のサービス

シームレスなグローバルサポートを提供します 24/7 多言語チーム, ペアリング エンドツーエンドのカスタマイズ材料の選択から精密エンジニアリングまで.

持続可能な革新

FSC認定の論文の先駆者, 大豆 & 厳密なUVインクと接着剤 持続可能性基準, EUと厳密に整合しています & 米国のエコスタンダード.