कस्टम मुद्रित पुस्तकों के लिए उन्नत विनिर्माण & नोटबुक

उन्नत मुद्रण समाधान के लिए समर्पित

पूर्व -विभाग: कोडक सुपर CTP प्लेटमेकिंग सिस्टम से लैस डिमैड रंग सटीकता के लिए हीडलबर्ग रंग अंशांकन के साथ जोड़ा गया.

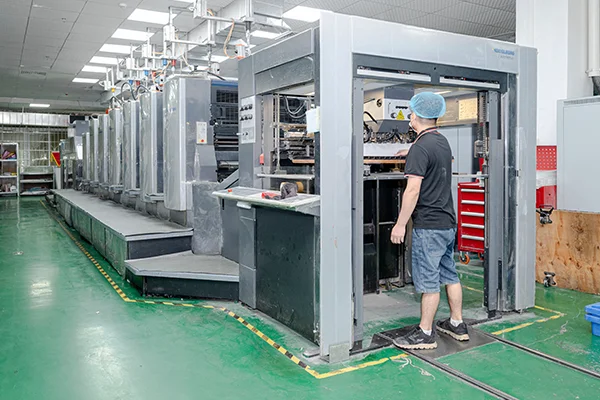

अत्याधुनिक प्रेस: एक अगली-जीन हीडलबर्ग शामिल है 6+1 बेल्ट ऑयल-पासिंग ऑटो-ड्राईिंग प्रेस, दो हाई-स्पीड कोमोरी लिथ्रोन 4-कलर प्रेस, और एक बहुमुखी 4+4 जटिल मल्टीटोन नौकरियों के लिए आठ-रंग हाइब्रिड प्रेस.

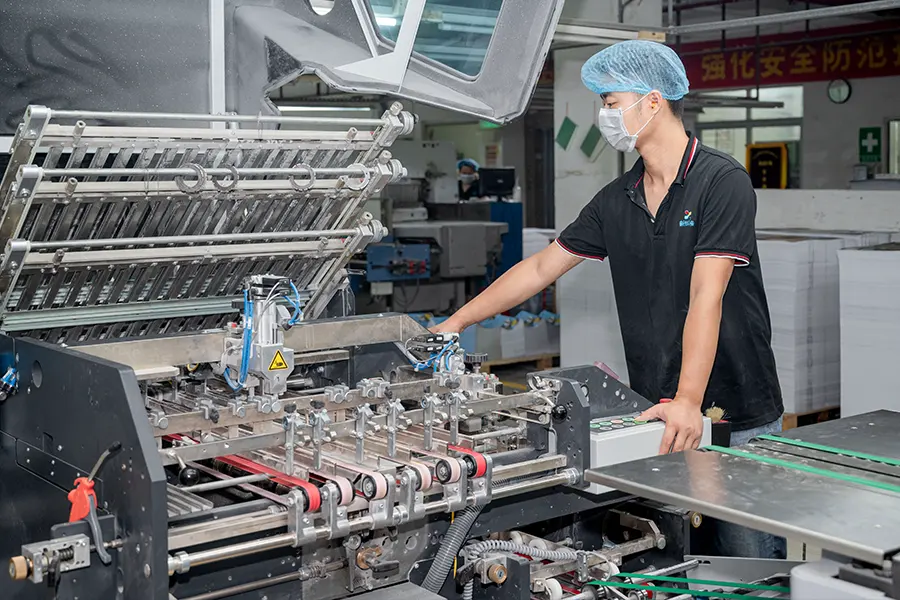

स्वचालित समापन: पूरी तरह से स्वचालित बाइंडिंग या हार्डकवर सिस्टम के साथ सहज एकीकरण और बीस्पोक डिटेलिंग के लिए छह समर्पित मैनुअल लाइनें.

उन्नत विनिर्माण उपस्कर

प्लेट मेकिंग मशीन

कोडक मैग्नस Q800 प्लेट सेट

- गति लाभ

- उन्नत स्वचालन

- गुणवत्ता लाभ

अंकीय थर्मल प्लेट प्रोसेसर

फूजी एलपी -1310HII

- पर्यावरणीय दक्षता

- बढ़ाया स्वचालन

- उच्च गुणवत्ता वाला आउटपुटप्रिंटिंग

बुटीक बॉक्स कटिंग प्रूफिंग मशीन

Aokedcz721310

- नवगणित & तेजी से काम करने का अनुभव

- टच स्क्रीन से सुसज्जित & मिलनसार मशीन इंटरफ़ेस

- एकीकृत मशीन डिजाइन & अधिक स्थिर और कलात्मक

बड़े वर्मेट इंकजेट प्लॉटर

एचपी डिजाइनजेट T770 प्रिंटर

- उच्च गुणवत्ता वाला आउटपुट रिज़ॉल्यूशन

- कुशल प्रदर्शन

- विभिन्न बड़े-प्रारूप अनुप्रयोगों के लिए उपयुक्त

- ऑपरेशन और स्टैंडबाय मोड के दौरान ऊर्जा-बचत

प्लेट झुकने और पंचिंग मशीन

TY-200pb

- बढ़ाया दक्षता

- अधिकतम लागत बचत करें

- के साथ आरओआई में सुधार किया 145 दिन

- उपयोगकर्ता के अनुकूल संचालन

डिजिटल प्रूफिंग मशीन

EPSON PRO9908

- अल्ट्रैक्रोम PRO12 स्याही प्रणाली

- प्रिसिजन कोर माइक्रो टीएफपी प्रिंटहेड

- बड़ा प्रारूप आउटपुट

- असाधारण रंग सटीकता

- उच्च मीडिया संगतता

- स्वचालित रखरखाव & आसान कामकाज

चार रंग मुद्रण मशीन

S40SP पर्ची

- सिंगल-पास परफेक्टिंग (सपा) तकनीकी

- उच्च गति आउटपुट से 15,000 प्रति घंटे-सुप्रेस प्रिंट की चादरें

- उत्कृष्ट रंग स्थिरता बनाए रखता है & तेज छवि प्रजनन

- कम समय के लिए तैयार समय & डाउनटाइम को कम से कम करें

- पर्यावरण के अनुकूल संचालन

- बहुमुखी सब्सट्रेट सीमा

छह रंग और यूवी प्रिंटिंग मशीन

हीडलबर्ग सीडी 102-6+एल

- 6-रंग विन्यास + कोटर एकक

- -विस्तृत सब्सट्रेट रेंज

- उच्च गति प्रदर्शन तक 15,000 प्रति घंटे चादरें

- सटीकता परिशुद्धता & रंग संगतता

- पर्यावरण के अनुकूल संचालन

- स्वचालन & त्वरित परिवर्तन

लिथ्रोन 840 आठ रंग मुद्रण मशीन

हीडलबर्ग LS840p

- 8-रंग परफेक्टिंग प्रेस (4+4 विन्यास)

- उन्नत स्वचालन & सहज प्रचालन इंटरफ़ेस

- उच्च गति प्रदर्शन तक 18,000 प्रति घंटे चादरें

- बहुमुखी सब्सट्रेट संगतता

- सटीक रंग & गुणवत्ता नियंत्रण

स्वत: काठी सिलाई

मुलर मार्टिनी सैडल स्टिचर

- प्रति घंटे 14,000-20,000 चक्र तक उच्च उत्पादन की गति

- मॉड्यूलर और लचीला विन्यास

- उच्च सिलाई गुणवत्ता

- उन्नत स्वचालन

- सहज प्रचालन

- स्वरूपों की विस्तृत श्रृंखला

- विश्वसनीय फीडिंग और टकराव

- इनलाइन परिष्करण क्षमता

- स्थायित्व और स्विस इंजीनियरिंग

सिलाई मशीन

मुलर मार्टिनी वेंचुरा 3215

- उच्च गति धागा सिलाई

- सटीक संरेखण & सिलाई

- स्वचालन & आसान कामकाज

- व्यापक प्रारूप लचीलापन

- स्वचालित उत्पादन लाइनों के साथ संगतता

फाड़ना मशीन

योंगशुन वाईएस -108

- हॉट स्टैम्पिंग & एक पास में डाई-कटिंग

- उच्चा परिशुद्धि & पंजीकरण सटीकता

- स्वत: भोजन & वितरण तंत्र

- मजबूत दबाव & टिकाऊ निर्माण

- व्यापक सामग्री संगतता

स्वत: अतीत मशीन

राउंड ZY440-A

- स्वत: तह & बनाने

- उच्च उत्पादकता प्रति मिनट 25-35 बक्से तक की गति

- परिशुद्धता स्थिति प्रणाली

- बहुमुखी बॉक्स प्रकार संगतता

- संक्षिप्त परिरूप

स्वत: पंचिंग मशीन

HB-420

- स्वत: कठोर बक्से का निर्माण

- प्रति मिनट 20-30 बक्से तक उच्च उत्पादन की गति

- सटीक स्थिति & बनाने

- कई बॉक्स प्रकारों का समर्थन करता है

- टचस्क्रीन नियंत्रण & पीएलसी प्रणाली

- टिकाऊ & अंतरिक्ष-कुशल डिजाइन

सही बाध्यकारी मशीन

मुलर मार्टिनी 3006

- हाई-स्पीड बाइंडिंग प्रदर्शन तक 6,000 प्रति घंटे किताबें

- उत्कृष्ट बाध्यकारी गुणवत्ता

- लचीला पुस्तक प्रारूप हैंडलिंग

- उन्नत गोंद अनुप्रयोग प्रणाली

- टचस्क्रीन नियंत्रण & स्वचालन

- इनलाइन एकीकरण सक्षम

स्वत: डबल-पक्षीय अस्तर मशीन

यासी पूरी तरह से स्वचालित डबल-पक्षीय अस्तर मशीन + यासी लैमिनेटिंग लिंकेज लाइन SL60

- दोहरे पक्षीय सटीक gluing

- उच्च गति, सतत संचालन

- इंटेलिजेंट पेपर फीडिंग सिस्टम

- सटीक संरेखण & तह

- एकीकृत फाड़ना & सुखाने

- कॉम्पैक्ट और मॉड्यूलर डिजाइन

- ऊर्जा कुशल ताप प्रणाली

कागज को मोड़ने वाली मशीन

हीडलबर्ग तह मशीन

- उच्च परिशुद्धता तह

- बहुमुखी तह विन्यास

- मॉड्यूलर अभिकर्मक

- उत्कृष्ट स्थायित्व & विश्वसनीयता

- स्वचालित विशेषताएं

गुणवत्ता-संचालित पुस्तकें मुद्रण प्रक्रिया

सामग्री की तैयारी से लेकर परिष्करण तक, उच्च-गुणवत्ता सुनिश्चित करना, टिकाऊ, और नेत्रहीन पुस्तक उत्पाद.

01

छपाई

सतह समापन

03

सांचे को काटना

04

तह

05

बाइंडिंग

06

गुणवत्ता नियंत्रण

07

पैकिंग & भंडारण

08

शिपिंग

गुणवत्ता नियंत्रण प्रक्रिया: हर विस्तार में उत्कृष्टता सुनिश्चित करना

कच्चे माल से लेकर तैयार उत्पादों तक, हम हर कदम उच्चतम मानकों को पूरा करने के लिए एक कठोर गुणवत्ता नियंत्रण प्रक्रिया को लागू करते हैं.

सटीक निरीक्षण और सख्त जाँच के माध्यम से, हम सुरक्षित वितरित करते हैं, टिकाऊ, और हमारे ग्राहकों के लिए स्थायी मुद्रण सेवाएं.

अवस्था 1: कच्चे माल निरीक्षण & भंडारण

कच्चे माल निरीक्षण & भंडारण

- नमी नियंत्रण: हम कागज के लिए इष्टतम आर्द्रता के स्तर को सत्यापित करने के लिए नमी उपकरणों का उपयोग करते हैं, स्याही, और कोटिंग्स, युद्ध को रोकना या विसंगतियों को प्रिंट करना.

- बयान (आवक गुणवत्ता नियंत्रण): कच्चे माल के कागज का निरीक्षण करें, आईएनके, गोदाम भंडारण से पहले विशिष्टताओं के साथ दोष और अनुपालन के लिए फाड़ना फिल्में.

- सामग्री भंडार: स्वीकृत सामग्री लॉग इन की जाती है और नियंत्रित पर्यावरणीय परिस्थितियों में कच्चे माल के गोदाम में संग्रहीत की जाती है.

अवस्था 2: पूर्व-प्रेस तैयारी

पूर्व-प्रेस तैयारी

- कागज की कटाई: सटीक कटिंग मशीनों का उपयोग करके आवश्यक आयामों के लिए कच्चे कागज को ट्रिम करें.

- आरोपण (प्लेट लेआउट): इष्टतम प्लेट संरेखण और कुशल मुद्रण के लिए डिजिटल रूप से पृष्ठों की व्यवस्था करें.

- प्लेट एक्सपोज़र & धुलाई: अवशिष्ट रसायनों को हटाने के लिए डिजिटल लेआउट और प्लेट धोने के यूवी लाइट ट्रांसफर के माध्यम से प्रिंटिंग प्लेट बनाएं.

अवस्था 3: मुद्रण प्रक्रिया नियंत्रण

मुद्रण प्रक्रिया नियंत्रण

- colorimeter: संदर्भ मानकों के खिलाफ रंग विचलन को मापें.

- रंग परीक्षण तंत्र: मास्टर प्रूफ के साथ बैच-टू-बैच रंग स्थिरता सुनिश्चित करें.

- बार कोड मीटर: मान्य बारकोड स्पष्टता, आकार, और स्कैनबिलिटी.

- यूपीएम कैलीपर: प्रिंट दबाव और गुणवत्ता का अनुकूलन करने के लिए कागज की मोटाई एकरूपता की निगरानी करें.

- IPQC (इन-प्रोसेस क्वालिटी कंट्रोल): दोषों के लिए वास्तविक समय के निरीक्षण का संचालन करें, जैसे कि गलत और स्याही स्मूडिंग.

अवस्था 4: प्रेस-प्रेस प्रोसेसिंग & इन-प्रोसेस क्यूसी

प्रेस-प्रेस प्रोसेसिंग & इन-प्रोसेस क्यूसी

- सतह का उपचार: कोटिंग्स लागू करें, जैसे कि चमक/मैट फाड़ना, स्थायित्व और सौंदर्यशास्त्र के लिए.

- फाड़ना: संरचनात्मक कठोरता के लिए सब्सट्रेट के लिए बॉन्ड मुद्रित चादरें.

- सांचे को काटना: अंतिम आयामों के लिए सटीकता का उपयोग करने वाले उत्पादों को आकार दें.

- IPQC रीचेक: आयामी सटीकता को सत्यापित करें, आसंजन गुणवत्ता, और सतह खत्म अखंडता.

अवस्था 5: अंतिम निरीक्षण & पैकेजिंग

अंतिम निरीक्षण & पैकेजिंग

- ओक्यूसी (निवर्तमान गुणवत्ता नियंत्रण): पैकेजिंग अखंडता के लिए ऑडिट तैयार किताबें, लेबलिंग सटीकता, और ग्राहक विनिर्देशों का अनुपालन.

- भंडारण: स्वीकृत उत्पादों को जलवायु-नियंत्रित शर्तों के तहत तैयार माल गोदाम में संग्रहीत किया जाता है.

आधिपत्य प्रमाणीकरण

Xinyi मुद्रण इको-प्रमाणित है, स्थायी प्रथाओं के लिए प्रतिबद्ध, और गुणवत्ता के लिए हरी सामग्री और ऊर्जा-कुशल प्रक्रियाओं का उपयोग करता है, पर्यावरण-सचेत पुस्तक मुद्रण.

Xinyi अंतर का अन्वेषण करें

तकनीकी उत्कृष्टता

हीडलबर्ग द्वारा संचालित, कोमोरी डिजिटल प्रेस और अन्य पेशेवर उत्पादन उपकरण, हम सटीक-इंजीनियर गुणवत्ता सुनिश्चित करते हैं और उच्च दक्षता विनिर्माण

लागत-स्मार्ट लचीलापन

हम गतिशील बाजार की मांगों को पूरा करने के लिए दुबला उत्पादन वर्कफ़्लोज़ और एकीकृत लॉजिस्टिक्स नेटवर्क के माध्यम से स्केलेबल ओईएम भागीदारी को सक्षम करते हैं.

ग्राहक-केंद्रित सेवा

हम सहज वैश्विक समर्थन के माध्यम से प्रदान करते हैं 24/7 बहुभाषी टीम, के साथ जोड़ा गया अंत-से-अंत अनुकूलनसामग्री चयन से सटीक इंजीनियरिंग तक.

सतत नवाचार

हम एफएससी-प्रमाणित कागजात पायनर करते हैं, सोया & यूवी स्याही और चिपकने वाले जो सख्त मिलते हैं स्थिरता मानदंड, यूरोपीय संघ के साथ कठोरता से गठबंधन & यूएस इको-स्टैंडर्ड्स.